FULLY AUTOMATIC CUTT OFF MACHINES

Fast Automatic circular saw for sawing off pipes / tubes and solid rods for a perfect matching fit to tack weld end fittings of rigid piping assemblies. Highly efficient and productive equipment in the pipe assembly line

CNC BENDING MACHINE FOR LARGE DIA PIPES

Perfectly suitable for manufacturing concrete conveying pipes of complicated critical shapes such as “S” bend and angle bends

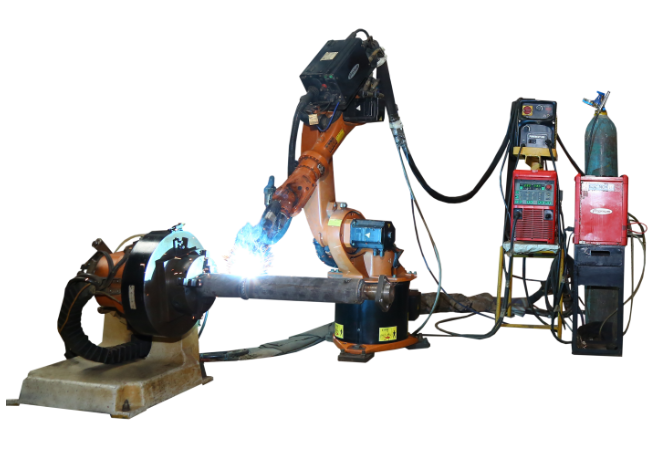

KUKA WELDING AND PLASMA CUTTING ROBOT(German make)

modern cutting edge technology cnc self teaching welding robot made in germany for complicated perfect quality mig welding and plasma profile cutting

ORBITAL TIG WELDING

orbital tig welding machine with avc/osc fully software based automatic self regulating uniform high quality tig welding

SOFTWARE BASED MANUAL MIG AND TIG WELDING MACHINES (German make)

manual mig and tig welding machines made in germany. automatic arc and metal deposit control for defect free welding

CNC Bending machines

3 axis and 2 axis cnc pipe bending machines for bending pipes and tubes for rigid pipe assemblies

7 TANK DEGREASING DERUSTING AND PHOSPHATING PLANT

CAPTIVE POWDER COATING PLANT

standard pre powder coating process preparing rigid piping assemblies for powder coating

HIGH PRESSURE HYDRAULIC TESTING EQUIPMENT

rigid pipe assemblies are tested for welding leaks up to 1000 bar pressure